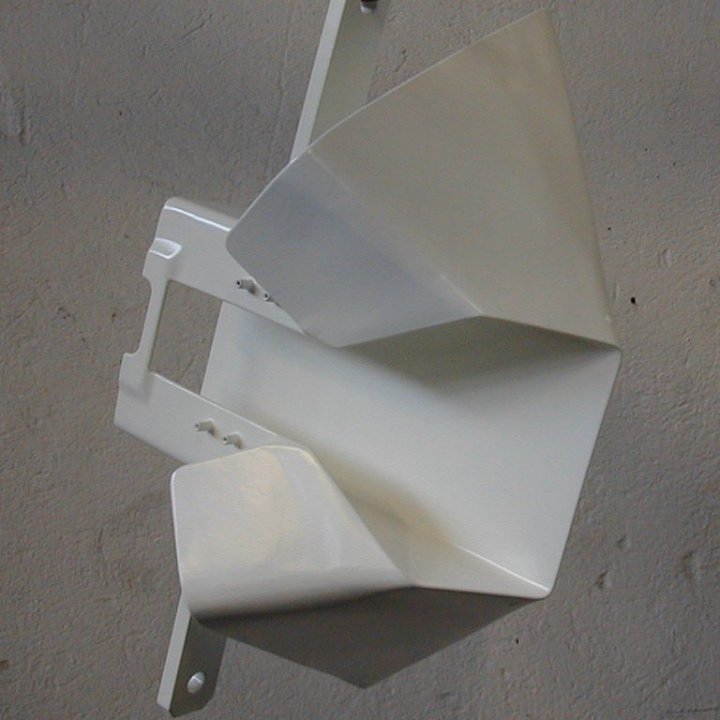

Polymeric coatings

Coatings

Polymeric coatings

Zocca Coatings provides polymeric coatings such as PTFE, FEP, PFA, ETFE, PEEK, Polyurethanes, Silicones and Resins of a Ceramicand Carbon-ceramic nature for applications at very high temperature developed with Sol-Gel technology. . Metal, plastic and carbon fibre surfaces can be coated with thickness ranging from 5 to 500 um.

- Exceptional non-stick behaviour

- Low friction coefficient

- Excellent heat resistance

- Cryogenic stability

- Water repellency and hydrophobicity/ Non-wetting

- Corrosion resistance

- High dielectric strength

- Packaging

- Pharmaceutical & Medical

- Food

- Aeronautical

- Automotive

- Chemical and Electrical

- Printing and Thermoforming

- Dry cleaning

TYPES OF COATINGS

The families of coatings and some of the advantages they can offer are illustrated below:

Coatings based on ceramic nanoparticles represent the industrial development of ceramic coatings used in cookware and bakeware. Zocca offers a product line described as “carbon ceramics” that can be applied on metals and metal alloys, plastics (e.g. rapid prototyping parts), carbon fibre and others. Read More…

Properties:

Anti-stick properties and low friction coefficient, transparent finish.

Applications:

The defence sector, application at very high temperatures (even over 1000°C).

Different fluoropolymer-based coatings, both monolayer and multilayer, are available: PTFE, PFA, FEP ETFE, HALAR. Coatings loaded with other resins are also available for even higher performance. Zocca obtained the qualification of Licensed Industrial Applicator from Du Pont de Nemours, a global leading company for fluoropolymers. Read More…

Properties:

Outstanding non-stick behaviour, low friction coefficient, excellent thermal resistance, cryogenic stability, chemical resistance, water repellency, high dielectric strength.

Applications:

Suitable for food contact applications according to the European and American standards (FDA).

Multilayer Ceramic + fluoropolymer coatings consist of a lower ceramic layer applied with Thermal Spray technology, and an upper fluoropolymeric layer. Read More…

Properties:

Outstanding wear resistance

Applications:

Welding rods, parts subject to high stresses.

Coatings in polyurethanes and silicon rubbers, can be created through casting and spray or brush painting.

Properties:

Wear resistance, protection against impact, increase of grip, noise reduction, excellent non-stick properties, available in a variety of colours and hardnesses.

Applications:

Situations in which grip strength is required, glues and adhesive tapes, vibratory mould cups, paper industry, ceramics processing, textile industry, pharmaceutical packaging machines, food contact applications according to the European and American standards.

The additive grades with PTFE or other fluoropolymers combine the sliding properties of fluorinated coatings with the wear resistance typical of PEEK polymer; the FDA certifications that accompany them allow their application in all fields.

Properties:

High wear and abrasion resistance, excellent release properties, continuous use possible till 260° C.

Applications:

Food contact applications according to the American standards (FDA), multisectoral applications.

These coatings are applied either via electrostatic painting or through immersion in a fluidized bed. The latter technique consists of introducing the preheated part into a tank filled with the raw coating material as fine powder.

Properties:

Excellent dielectric strength, very good chemical resistance against a wide range of substances, available in a variety of colours, thickness adjustment up to a few tenths of a millimetre.

Applications:

Electrical insulation, surface protection.

Polyamide 11 coatings can be applied either via electrostatic painting or through immersion in a fluidized bed. They are obtained from powders of 100% vegetable origin. Read More…

Properties:

High wear resistance, very good impact properties, outstanding chemical resistance to grease, hydrocarbons, acids, bases and salts, outstanding resistance to weathering and UV rays, suitable for food contact applications.

Applications:

Automotive, fluids transportation, textile industry, food sector, pharmaceutical and medical industry, urban furniture.

Coatings in modified Polyolefins are obtained from fine powders through immersion in a fluidized bed. These coatings can withstand significant impact, extreme weather conditions, chemical attack, corrosion and atmospheric pollutants. Read More…

Properties:

Excellent adhesion on metals, good insulating properties, resistance to abrasive wear and impact, available in a variety of colours

Applications:

Fence rods and panels, signboards, street furniture, balustrades, pipes for fluid transportation (also for drinking water), cable supports and sheaths, garden furniture, gutter supports and metal items in general.

FEP ON IMPELLER FOR AUTOMATIC MACHINE

PFA ON DRYER BASKET

FEP ON CHEESE DISPENSER

PTFA ON COFFEE BOILER MACHINE

ELECTRICAL INSULATION ON COPPER

HALAR ON PULLEYS

HALAR COATING ON VOLUMETRIC COMPRESSOR

SILICON OXIDES ON PRINTED CIRCUIT BOARD

PTFE ON ALUMINIUM CONTAINERS FOR THE COOKING OF FOOD

POLYURETHANE 60 SHORE A ON CLAMPS

FOOD CONTACT GRADE PTFE ON CREPES PLATE

FEP ON LEVEL MARKERS

PTFE COATING ON PACKAGING MACHINES ROLLERS

CARBON CERAMIC COATING ON FIBREGLASS ROLLER

CERAMIC SOL GEL ON STEEL ROLLERS

POWDER FEP COATING ON POLYURETHANE MOULD

FEP ON RUBBER MOULDS

FOOD CONTACT GRADE PTFE ON WAFFLES PLATES

FDA POLYURETHANE ON DRY PASTA CONVEYING CUPS

PTFE ON VIBRATING CUP

POWDER FEP ON THERMOFORMING MOULDS

POWDER FEP ON TYRE MOULDS

PTFE COATING ON STEAK PLATE

PTFE ON WELDING BARS FOR PACKAGING MACHINE

FOOD CONTACT GRADE SILICONE ON INDUSTRIAL COMB

PFA ON FUMES EXTRACTION FAN

POLYURETHANE COATING ON VIBRATING CUP

POLYAMIDE 11 ON PASTA CONVEYOR SYSTEM

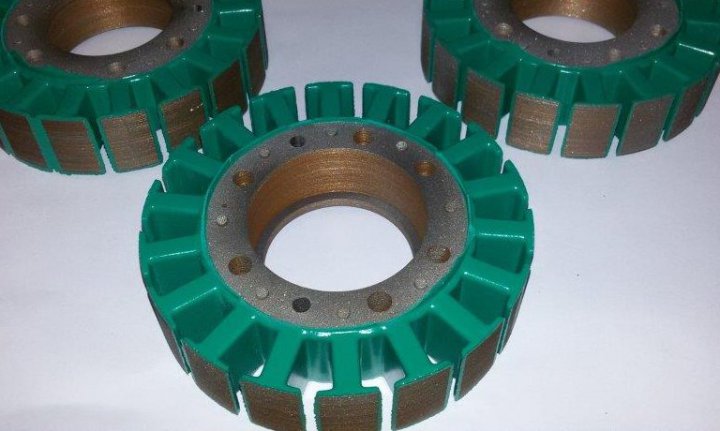

EPOXY COATING ON STATOR